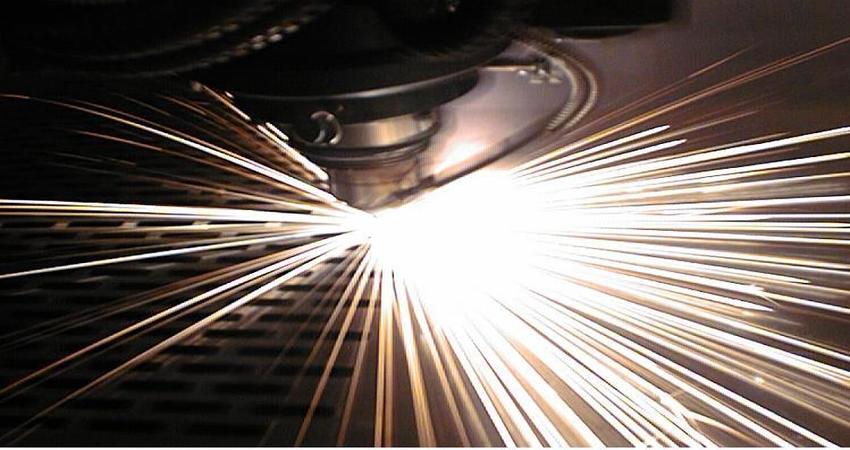

Laser cutting is an amazing manufacturing process mainly used by engineers in the manufacturing industry. Laser cutters use a focused beam to pierce a material specified by the designers.

Apart from cutting, laser cutters can also raster onto a workpiece by heating the surface of the workpiece. This process makes the prototyping quick.

Laser cutters are a convenient tool for prototyping and manufacturing; they are mainly used in machine shops on an industrial scale to cut huge pieces of materials. They are also used to create cheap and quick prototypes.

Also, laser cutters produce harmful fumes that are very risky. One way to reduce the risk is by using good quality parts like Bystronic laser parts or prima laser parts. Here are some other tips you can use to enhance your laser cutting.

Select a Software and Master it

Do you use Adobe Illustrator? Or are you handy with CorelDraw? There is no software that's the best, but if you like one, just stick to it.

There are many design software that supports laser cutter drivers. Such software are pretty standard among the 2D designs or some 3D designs. Here are a couple of software that you may already be familiar with or you may want to try out.

2D Design:

Inkscape: Open source software and free to use

CorelDRAW: Graphic design software with a huge number of tools and features

AutoCAD: Drawing software, primarily used by engineers and architects

Adobe Illustrator: Graphic design software for high-quality designs

3D Design:

SketchUp: 3D designing software comes with 30 days free trial

SolidWorks: 3D design software with multiple design package

Autodesk Fusion: Cloud-based platform for manufacturing process

Settings of Laser Cutting

Before performing the laser cutting process, it is good to know the settings of it. A laser cutter comes with primary settings as per the above image. The power represents the strength of a laser. Speed is how fast your laser will go. If it is too quick, it may not cut all the way, but a low speed can lead to melting or burning. So most of the time, you can stick to the moderate settings for the cutting to be fine.

Frequency determines the laser pulses during a cutting operation. The higher the frequency the cleaner the slash would be. But it is also okay to keep the frequency low to prevent flammable materials from catching fire.

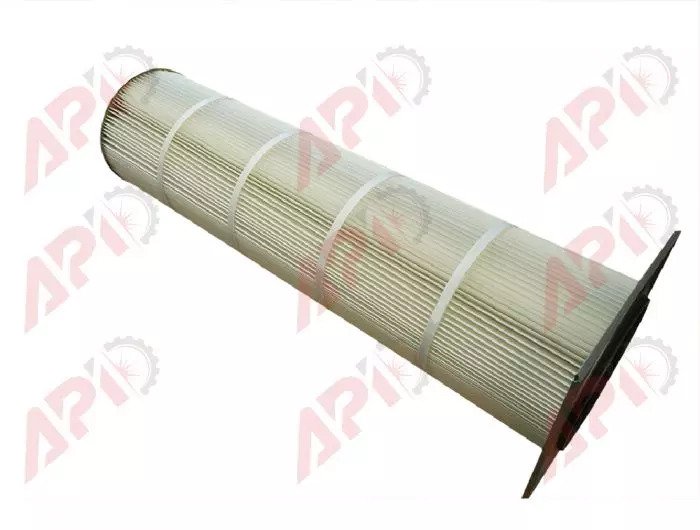

Use the Quality Spare Parts

When it comes to laser cutting, lasers majorly depend upon the consumables and parts. So whenever you are using any part or replacing it, make sure you are using top-quality parts. Bystronic laser parts and Amada laser parts are some of the best ones.

Amada and Bystronic parts come in a variety of ranges like focus lenses, nozzles, lens wizards, and much more.

You can also check out other brands such as Hypertherm, Mitsubishi, Mazak, Prima, etc.

Know the Material You Are Using

While designing with laser-cut, you should start thinking about what materials you will work upon. Are you designing a prototype? Then you should consider cheap materials like cardboard. Else you can use wood or any other metal.

Talking about wood, type matters! Wood could be soft or hard. A harder wood can produce a darker appearance than a softwood.

Another common material is acrylic. It is more fragile than wood. So be mindful of the spacing between the lines. To keep acrylic material nice and clean, putting on protective tape is the best way to go.

Types of Laser Cutters

There are three types of laser cutters:

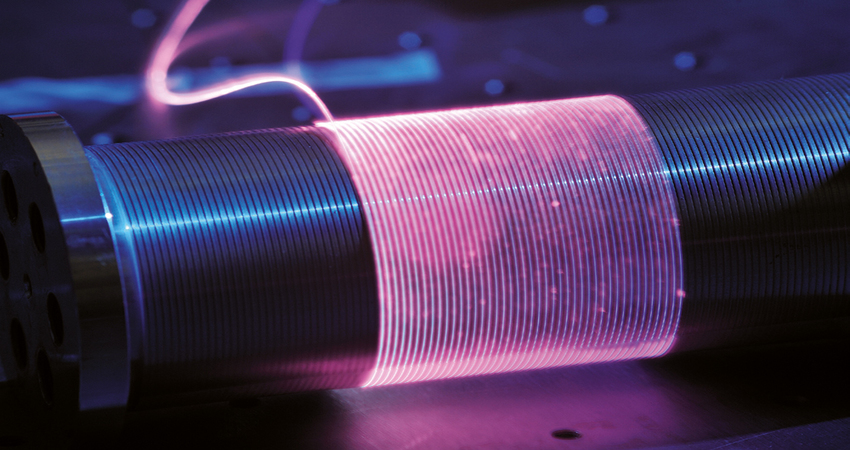

CO2 Lasers: The generated lasers have stimulated gas mixtures (majorly consists of carbon dioxide). CO2 is one of the most common types of laser cutter because it is inexpensive and can cut most materials like leather, acrylic, glass, wood, plastic, etc.

Neodymium Lasers: The laser consists of neodymium doped crystals. These lasers have small wavelengths as compared to CO2 but they are highly intensive. Which means they can cut through much thicker materials like plastics, metals, and some ceramics.

Fiber Lasers: The laser is usually doped with rare-earth elements such as erbium, dysprosium, and holmium. The laser has a wavelength similar to neodymium lasers. But they are built in such a way that they require less maintenance and can cut materials like metals and plastic.

Though they look very similar, they are distinct in terms of power or how they cut materials.

Thickness of Materials and Kerf

The focal point of the lens of the laser cutter cuts the material. On the other side of the material, the laser isn't as focused and the beam is slightly larger as compared to the focal point. This gap that the laser makes is basically known as kerf.

For example, the kerf on the saw blade is usually a rectangle. The laser cutter's kerf is slightly trapezoidal because the laser beam gets wider after its focal point. The kerf of the given laser determines the maximum thickness of the material it can cut. Because the laser will get thicker after its focal point. When the beam is thicker, then it is unfocused to cut it well.

Time to Cut

Now you might be ready to cut the material. It can take a few tries to find the ideal settings to cut your materials. Also, don't lose hope if your first few projects don't turn out to be successful. Keep in mind the above tips and use good quality consumable parts like the Bystronic parts. If you are happy with the results, don't forget to note them down for future reference.

Source: https://altpartsinc.wixsite.com/altpartsinc/single-post/6-tips-to-enhance-the-laser-cutting-process